Motsoako oa ho kopanya le ho hlatsoa metsi ka sekoahelo se bulehileng halofo

Video ea Mochini

Kopo

Motsoako o loketse tlhahiso ea mefuta e fapaneng ea lisepa tsa ho hloekisa le litlolo

linoko le lik'hemik'hale tse ling tse ntle lisebelisoa tse hlokahalang

Tshebetso le Likarolo

1. Motsoako oa PME-4000L o amohela 'mele oa pitsa o tsitsitseng, sekoahelo sa pitsa le 'mele oa pitsa o nang le khokahano ea flange o ke ke oa phahamisoa.

1.2 Homogenizer e nang le lebelo le phahameng e fapaneng e ka kopanya ka matla thepa e tala e tiileng le e metsi mme e ka qhala ka potlako thepa e ngata e sa qhibiliheng joalo ka AES, AESA, LSA, jj. nakong ea ts'ebetso ea tlhahiso ea sesepa sa metsi e le ho boloka tšebeliso ea matla le ho khutsufatsa nako ea tlhahiso.

2. Pitsa ea Mixer e entsoe ka ho tjheseletsa tšepe e sa ruseng ea mekhahlelo e meraro, lera le ka hare le amanang ka ho toba le thepa le entsoe ka tšepe e sa ruseng ea SUS316L e tsoang kantle ho naha, lera le bohareng la jakete le lera la ho thibela mocheso oa kantle li entsoe ka tšepe e sa ruseng ea 304, 'me' mele oa tanka le phaephe li pentiloe ka seipone kapa li matte, tse fihlelang litlhoko tsa GMP ka botlalo.

3. Sistimi ea ho hlohlelletsa e amohela ho kopanya lebota ka tataiso e habeli le phetoho ea lebelo la phetoho ea maqhubu, e le ho khotsofatsa sehlahisoa sa litlhoko tse fapaneng tsa theknoloji.

4. Mochini o amohela sistimi ea homogenizing ea potoloho ea kantle e ka tlase, enjene ea homogenizing e amohela Jeremane Siemens, 'me e lokisa lebelo la mochini oa homogenizing ka inverter ea taolo ea PLC Siemens ka har'a khabinete ea motlakase, 'me lebelo la homogenizing ke 0-2880r/min

5. Mochini o laoloa ke khabinete ea taolo ea elektroniki ea PLC e ikemetseng, khabinete e entsoe ka thepa ea tšepe e sa ruseng e tsoang kantle ho naha, likarolo tsa motlakase li entsoe ka Jeremane Schneider Electric, inverter le PLC li entsoe ka Jeremane Siemens, sesebelisoa ke Omron, 'me lisebelisoa tsa ts'ebetso li ka beoa leihlo ka lisebelisoa tsa skrine ea ho ama ea Siemens PLC. 'Me ka skrine ea ho ama ea Siemens ea khabinete ho laola lebelo la ho hlohlelletsa, lebelo la homogenization, taolo ea mocheso le tse ling.

Paramethara ea Tekheniki

| Mohlala | PME-4000L | |

| Buka ea ho Sebetsa | 4000L | |

| Moqolo oa Moralo | 5000L | |

| Enjene ea Homogenizer | Matla (KW) | 30KW |

| Lebelo la ho potoloha (r/min) | 0-3000 r/motsotso | |

| Motlakase oa ho Hlohlelletsa (Ho Kopanya ka Ntle) | Matla (KW) | 7.5KW |

| Lebelo la ho potoloha (r/min) | 0-60r/motsotso | |

| Motlakase oa ho Hlohlelletsa (Ho Kopanya ka Hare) | Matla (KW) | 15KW |

| Lebelo la ho potoloha (r/min) | 0-30r/motsotso | |

| Yuniti e Akaretsang ea Tekanyo (L*W*H) (mm) | 2300*2300* | |

| Mofuta oa ho Futhumatsa | Ho futhumatsa ka mouoane | |

| Hlokomela: haeba data e tafoleng e sa lumellane ka lebaka la ntlafatso ea tekheniki kapa ho fetoloa, ntho ea sebele e tla hlola. | ||

Lintlha tsa Sehlahisoa

Pitsa ea Mixer e entsoe ka ho tjheseletsa tšepe e sa ruseng e mekhahlelo e meraro, lera le ka hare le kopanang ka ho toba le thepa le entsoe ka tšepe e sa ruseng e tsoang kantle ho naha ea SUS316L, lera le bohareng la jakete le lera la kantle la ho thibela mocheso li entsoe ka tšepe e sa ruseng e 304, 'me' mele oa tanka le phaephe li pentiloe ka seipone kapa li matte, tse fihlelang litlhoko tsa GMP ka botlalo.

Sistimi ea ho Kopanya e Holimo

Sistimi ea ho kopanya ea pitsa e kholo e sebelisa ho hlohlelletsa lebota ka mahlakoreng a mabeli, 'me enjene ea ho hlohlelletsa e sebelisa enjene ea Jeremane ea Siemens ho fana ka ho kopanya ho sebetsang hantle le ho netefatsa ho kopanya ka botlalo metsoako ka pitseng e kholo.

Sistimi ea PME-4000L Mixer e kenyelletsa sehomogenizing mixer sa homogenizing sa ho hlatswa metsi sa 4000L, khabinete ea motlakase e laoloang ke PLC e ikemetseng, sistimi ea liphaephe, tanka ea polokelo ea tšepe e sa ruseng ea CG-8000L, sethala sa ho phahamisa motlakase, sethala sa tšepe e sa ruseng se nang le litšepe tsa polokeho le litepisi.

Karolo ea motsoako oa PME-4000L

Karolo ea Sekoahelo

Melemo ea pitsa ea ho kopanya metsi e nang le sekoahelo se bulehileng se lehlakoreng le le leng e kenyelletsa:

Ho eketsa thepa: Sekwahelo se bulehileng se lehlakoreng le le leng se nolofalletsa ho eketsa metsoako kapa thepa e tala nakong ea ts'ebetso ea ho kopanya, e leng se lumellang ho tenyetseha le taolo holim'a motsoako.

Tlhokomelo le ho hlwekisa: Mesebetsi ea ho hloekisa le ho hlokomela e ka ba bonolo ka sekoahelo se bulehileng se lehlakoreng le le leng, kaha se fana ka phihlello e lekaneng ea likarolo tse ka hare tsa pitsa ea ho kopanya.

Phihlello ea lisebelisoa: Ho ka ba bonolo ho kenya le ho tlosa lisebelisoa tsa ho kopanya ka pitseng ka sekoahelo se bulehileng se lehlakoreng le le leng, ho ntlafatsa bokhoni nakong ea ho seta le ho fetola.

Sistimi ea Homogenizer e ka tlase

Likarolo le mesebetsi ea mantlha ea homogenizer ea potoloho ea kantle e ka tlase e kenyelletsa:

Ho Kopanya ka Botlalo: Homogenizer e etselitsoe ho nolofatsa ho kopanya metsoako ka katleho, ho netefatsa boleng bo tsitsitseng ba sehlahisoa.

Homogenization: E kgona ho qhaqha le ho qhalanya dikarolwana kapa marothodi ka hara mokelikeli, e leng se fellang ka sehlahiswa se tshwanang le se tsitsitseng.

Ho Kopanya ka ho Koahela ka Botebo: Hangata lisebelisoa li khona ho fana ka matla a ho koahela ka botebo ho kopanya le ho etsa emulsify lintho tse fapaneng ka katleho.

Ho feto-fetoha ha maemo: Li-homogenizer tse ka tlase ho potoloho ea mali li ka sebelisoa bakeng sa mefuta e mengata ea lits'ebetso, ho kenyeletsoa le ho kopanya lino, li-suspension le li-emulsion.

Liparamente tse Laolehang: Li ka fana ka taolo holim'a lintlha tse kang lebelo la ho kopanya, phallo ea potoloho, le matla a ho khaola ho ntlafatsa ts'ebetso ea ho kopanya.

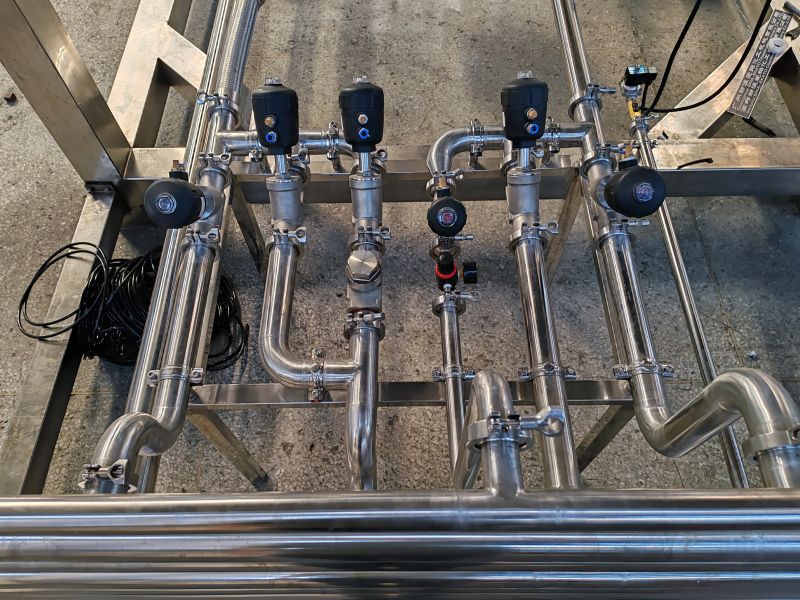

Sistimi ea Liphaephe

Phaephe ea Likhoerekhoere: Phaephe ena e sebelisetsoa ho tsamaisa metsi a litšila kapa litšila tse metsi ho tloha mochineng o kopanyang ho ea tsamaisong e loketseng ea ho lahla kapa ea ho phekola.

Phaephe ea ho Kena ka Mouoane: Phaephe ena e ikarabella bakeng sa ho kenya mouoane ka har'a sehokelo. Mouoane o ka sebelisoa ho futhumatsa le ho bolaea likokoana-hloko mokelikeli o ka har'a sehokelo.

Phaephe ea ho Kena ka Metsi a Pholileng: Phaephe ena e fana ka phallo ea metsi a pholileng ka har'a sehokelo ho laola mocheso oa mokelikeli nakong ea ts'ebetso ea ho kopanya, ho thibela ho chesa haholo.

Phaephe ea Moea e Hatelletsoeng: Phaephe ena e fa motjhini o hatelletsoeng moea, o ka sebelisoang bakeng sa ho sisinya, ho kenya moea moeeng, kapa lits'ebetso tse ling ka har'a phaposi ea ho kopanya.

Phaephe ea ho ntša mouoane: Phaephe ena e ikarabella bakeng sa ho lokolla mouoane ho tsoa ho motsoako ka mor'a hore e sebelisoe ts'ebetsong.

Phaephe ea ho Pholisa Metsi: Phaephe ena e sebelisetsoa ho tlosa metsi a pholileng ho tsoa ho motsoako ka mor'a hore e phethe mosebetsi oa eona oa ho laola mocheso oa mokelikeli.

Khabinete ea motlakase ea taolo e ikemetseng

Khabinete ea taolo e ikemetseng ea pitsa ea ho kopanya e hlatsoang ka metsi e na le likarolo tsa boleng bo holimo, ho kenyeletsoa le skrine ea ho ama ea Siemens PLC le sistimi ea taolo, hammoho le likarolo tsa motlakase tse tsoang Jeremane Schneider. Ho feta moo, inverter e tsoang Jeremane Siemens e lumella taolo e nepahetseng holim'a lebelo la enjene ea ho kopanya le enjene e kopantsoeng. Boemo bona ba taolo bo netefatsa ts'ebetso e sebetsang hantle le e nepahetseng ea ts'ebetso ea ho kopanya, e lumellang liphetoho tse nepahetseng ho fihlela liphetho tse lakatsehang tsa ho kopanya le ho kopanya.

Tšebeliso ea skrine ea ho ama ea PLC bakeng sa ho laola pitsa ea ho kopanya metsi e fana ka melemo e 'maloa. Tse ling tsa tsena li kenyelletsa:

Sebopeho se bonolo ho se sebedisa: Skrine sa ho ama se fana ka sebopeho se bonolo le se bonolo ho se sebedisa bakeng sa basebetsi ho laola le ho beha leihlo tshebetso ya ho kopanya. Sena se nolofatsa tshebetso mme se fokotsa tlhoko ya koetliso e batsi.

Taolo e nepahetseng: PLC (Programmable Logic Controller) e fana ka taolo e nepahetseng hodima diparamente tse kang lebelo la ho kopanya, mocheso le nako. Sena se nolofalletsa ho lokisoa ha tshebetso ya ho kopanya ho fihlela diphetho tse lakatsehang mme se netefatsa botsitso ba boleng ba sehlahiswa.

Bokhoni ba ho iketsetsa: Skrine sa ho ama sa PLC se dumella ho iketsetsa ditatelano le ditshebetso tse fapaneng tsa ho kopanya, ho fokotsa tlhoko ya ho kenella ka letsoho le ho ntlafatsa bokgoni ka kakaretso.

Tlhokomelo le ho rekota data: Sistimi e ka rekota le ho bonts'a data ea bohlokoa ea ts'ebetso, joalo ka ho kopanya liparamente, mocheso le nako, e leng se lumellang basebetsi ho beha leihlo le ho sekaseka ts'ebetso ka nako ea sebele.

Mechine e amanang

Sistimi ea Metsi ea Kalafo ea RO

Mochini oa ho Hlatsoa Botlolo ka Boiketsetso

Mochini oa ho omisa botlolo

Tanka ea polokelo e hloekisitsoeng

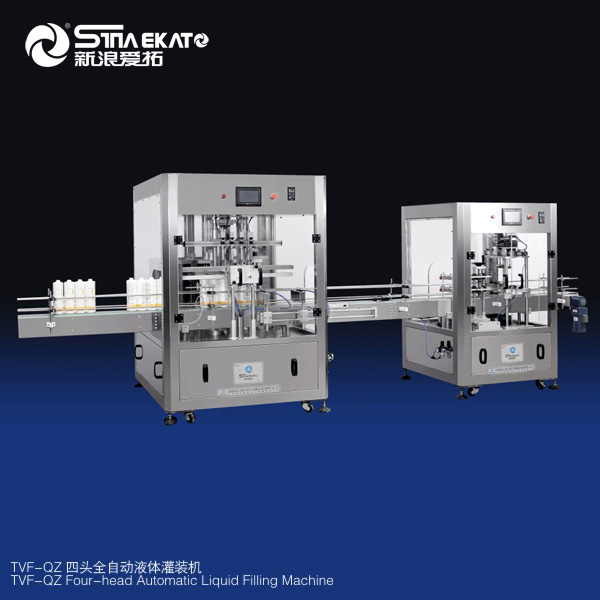

Mechini ea ho tlatsa metsi ka Auto Liquid

Mochini oa ho ngola mabitso ka boiketsetso

Boemo ba Khoebo

Ka tšehetso e tiileng ea Profinse ea Jiangsu Gaoyou City Xinlang Light

Fektheri ea Mechini le Lisebelisoa tsa Indasteri, tlas'a tšehetso ea setsi sa meralo sa Jeremane le indasteri ea naha ea leseli le lipatlisiso tsa lik'hemik'hale tsa letsatsi le letsatsi, 'me mabapi le baenjiniere ba baholo le litsebi e le motheo oa theknoloji, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. ke moetsi oa litsebi oa mefuta e fapaneng ea mechini le lisebelisoa tsa litlolo 'me e se e le khoebo ea lets'oao indastering ea mechini ea lik'hemik'hale ea letsatsi le letsatsi. Lihlahisoa tsena li sebelisoa liindastering tse kang: litlolo, meriana, lijo, indasteri ea lik'hemik'hale, lisebelisoa tsa elektroniki, jj., li sebeletsa likhoebo tse ngata tse tummeng naheng ka bophara le machabeng joalo ka Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japane Shiseido, Korea Charmzone, France Shiting, USA JB, jj.

Molemo oa Rōna

1. Ka boiphihlelo ba lilemo tse ngata ba ho kenya thepa ka tlung le machabeng, SINAEKATO e nkile mehato e mengata ea ho kenya thepa ka bongata mererong e meholo e makholo ka tatellano.

2. Khamphani ea rona e fana ka boiphihlelo ba maemo a holimo ba ho kenya merero ea litsebi le boiphihlelo ba tsamaiso.

3. Basebetsi ba rona ba tšebeletso ea kamora thekiso ba na le boiphihlelo bo sebetsang ba tšebeliso le tlhokomelo ea lisebelisoa 'me ba fumana lithupelo tsa tsamaiso.

4. Re fa bareki ba tsoang hae le linaheng tse ling mechine le lisebelisoa, thepa e tala ea litlolo, thepa ea ho paka, boeletsi ba tekheniki le tšebeletso e 'ngoe ka tieo.

Tlhahiso ea Morero

Tsepamisa maikutlo holim'a boleng bo bong ntle le litifikeiti tsa bongata

Belgium

Saudi Arabia

Afrika Boroa

Mehloli ea Lintho tse bonahalang

80% ea likarolo tse kholo tsa lihlahisoa tsa rona li fanoa ke bafepedi ba tummeng lefatšeng. Nakong ea tšebelisano-'moho ea nako e telele le phapanyetsano le bona, re bokelletse boiphihlelo bo bongata ba bohlokoa, e le hore re ka fa bareki lihlahisoa tsa boleng bo holimo le tiisetso e sebetsang haholoanyane.

Moreki oa Tšebelisano-'moho

Tšebeletso ea Rōna

* Letsatsi la ho tlisa ke matsatsi a 30 ~ 60 feela

* Moralo o ikhethileng ho latela litlhoko

* Tšehetsa fektheri ea tlhahlobo ea video

* Tiisetso ea lisebelisoa bakeng sa lilemo tse peli

* Fana ka video ea ts'ebetso ea lisebelisoa

* Tšehetso ea video e hlahloba sehlahisoa se felileng

Ho paka le ho Romela

Setifikeiti sa Thepa

Moikarabelli

Jessie Ji

Selefouno/Sesebelisoa sa eng/Wechat:+86 13660738457

Imeile:012@sinaekato.com

Webosaete ea semmuso:https://www.sinaekatogroup.com