Mochini o sa Fetoheng oa ho kopanya Vacuum Emulsifying Mixer oa Sefahleho sa 'Mele oa Sefahleho oa Cream Lotion Homogenizing

Video ea Mochini

Kopo

| Litlolo tsa letsatsi le letsatsi | |||

| setlolo sa moriri | maske ea sefahleho | setlolo se nolofatsang | setlolo sa letsatsi |

| tlhokomelo ea letlalo | botoro ea shea | setlolo sa 'mele | setlolo sa letsatsi se sireletsang letlalo letsatsing |

| setlolo | setlolo sa moriri | peista ea litlolo | Setlolo sa BB |

| setlolo | mokelikeli oa ho hlatsoa sefahleho | mascara | motheo |

| 'mala oa moriri | setlolo sa sefahleho | serum ea mahlo | jeli ea moriri |

| dae ea moriri | setlolo sa molomo | serum | gloss ea molomo |

| emulsion | molomo | sehlahisoa se tiileng haholo | shampoo |

| toner ea botle | setlolo sa letsoho | setlolo sa ho beola | setlolo se nolofatsang |

| Lijo le Meriana | |||

| chisi | botoro ea lebese | setlolo | ketchup |

| mosetareta | botoro ea linate | mayonesiise | wasabi |

| sesepa sa meno | margarine | Ho apara salate | soso |

Tshebetso le Likarolo

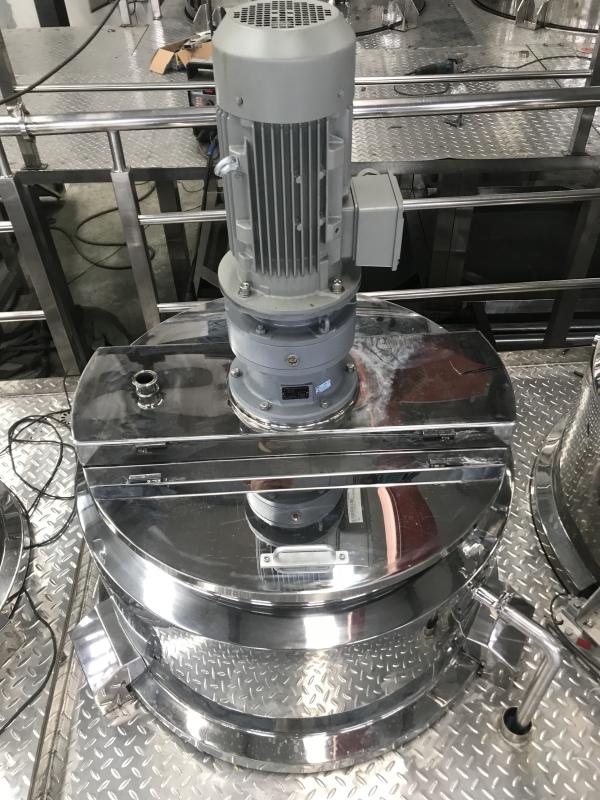

1. Mekhoa ea ho kopanya e kopanyang ka tsela e habeli le ho kopanya ribone ea helical. Seqhoqho sena se na le liribone tse peli tse bōpehileng joaloka helical tse kopantsoeng 'me li potoloha ka mahlakoreng a fapaneng. Se na le litšobotsi tse latelang: Ho Kopanya ka Bokhabane: Moralo oa helix e habeli oa mahare a ribone o netefatsa ho kopanya thepa ka katleho ha o ntse o qoba matheba a shoeleng, Ho Tšoara ka Viscosity e Phahameng: Mofuta ona oa seqhoqho o loketse haholo bakeng sa ho sebetsana le thepa e nang le viscous e phahameng, joalo ka likhomaretsi, li-pesta le li-gel tse rutiloeng. Shear: Ketso e bonolo ea ho kopanya mahare a ribone e fokotsa ho kuta ho ka bang teng mefuteng e meng ea metsoako.

2. Ho kopanya ha triple ho amohela sesebelisoa sa ho fetola maqhubu se kentsweng kantle ho naha bakeng sa ho fokotsa lebelo. Se ka fihlelang litlhoko tse fapaneng tsa theknoloji.

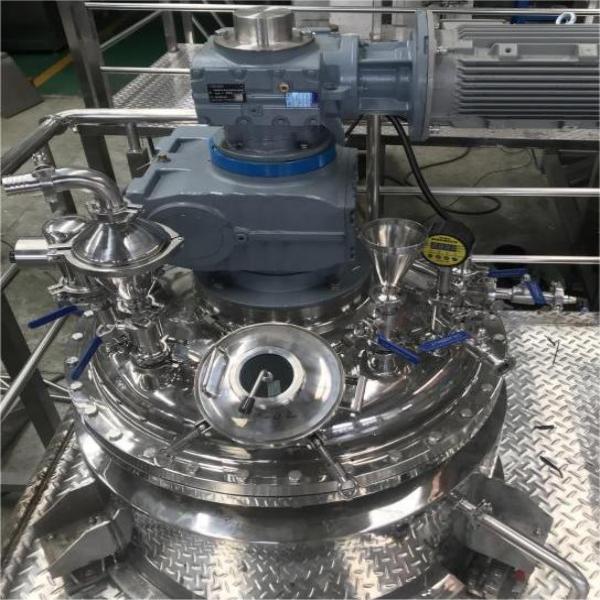

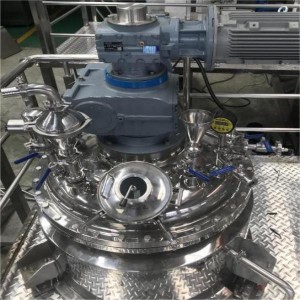

3. Sebopeho sa homogenizing se entsoeng ka theknoloji ea Jeremane se amohela phello ea tiiso ea mechini e habeli e tsoang kantle ho naha. Lebelo le phahameng ka ho fetisisa la ho potoloha ha emulsifying le ka fihla ho 3000 rpm 'me botenya bo phahameng ka ho fetisisa ba ho kuta bo ka fihla ho 0.2-5 u m. Ho hloekisa ka vacuum ho ka etsa hore thepa e fihlelle tlhoko ea ho ba e sa bolaeng likokoana-hloko.

4. Mochini o sebelisa sistimi ea potoloho ea ka hare ho fihlela phello e ts'oanang le e ntle ea ho kopanya metsoako. Thepa e potoloha ka har'a mochini, e feta lipotolohong tse ngata tsa ho kopanya metsoako, ho fihlela botsitso bo lakatsehang bo fihlelleha.

5. Ho monya thepa ea vacuum hoa amoheloa, haholo-holo bakeng sa thepa ea phofo, ho monya vacuum ho ka qoba lerōle. 'Mele oa pitsa o tjheselletsoa ka poleiti ea tšepe e sa hloekang ea mekhahlelo e meraro e tsoang kantle ho naha.

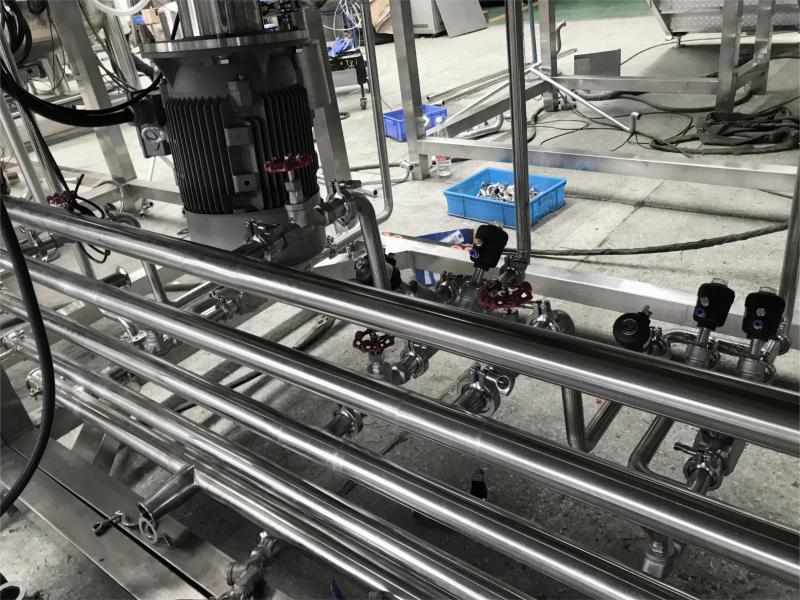

6. 'Mele oa tanka le liphaephe li sebelisa ho bentša seipone, e leng se lumellanang ka botlalo le litlhoko tsa GMP. Ho ea ka litlhoko tsa theknoloji, 'mele oa tanka o ka futhumatsa kapa oa pholisa thepa.

7. Mekhoa ea ho futhumatsa e kenyelletsa haholo-holo ho futhumatsa ka mouoane kapa ho futhumatsa ka motlakase. Ho netefatsa hore taolo ea mochini oohle e tsitsitse haholoanyane, lisebelisoa tsa motlakase li amohela litlhophiso tse tsoang kantle ho naha, e le hore li fihlelle maemo a machaba ka botlalo.

8. Ho Hloekisa le ho Hlokomela Habonolo: Moralo wa mmele wa pitsa o tsitsitseng o etsa hore ho be bonolo ho hlwekisa le ho hlokomela mochini. Sena se fokotsa kotsi ya tshilafalo nakong ya tshebetso ya ho kopanya. Mochini o na le CIP, e ka nolofalletsang sistimi ya CIP ya mosebedisi ho hlwekisa mochini.

9. Khabinete ea taolo ea Siemens PLC le skrine ea ho ama ea Siemens Ho netefatsa hore taolo ea mochini oohle e tsitsitse haholoanyane, lisebelisoa tsa motlakase li amohela litlhophiso tse tsoang kantle ho naha, e le hore phanele ea taolo e be bonolo ho e sebelisa: Mochini o na le phanele ea taolo e bonolo ho e sebelisa, e lumellang basebetsi ho fetola lebelo, mocheso le liparamente tse ling habonolo ha ho hlokahala

Paramethara ea Tekheniki

| Mohlala | Bokgoni (L) | Matla a ho Kopanya (KW) | Lebelo la ho Kopanya (r/min) | Matla a Homogenizer (KW) | Lebelo la ho kopanya lintho tse tšoanang | Mokhoa oa ho Futhumatsa | Moeli oa Vacuum (Mpa) |

| SME-DE 50L | 50L | 1.5KW | 0-63RPM | 3KW | 0-3000RPM | Ho futhumatsa ka motlakase kapa ka mouoane | -0.09 |

| SME-DE 100L | 100L | 2.2KW | 0-63RPM | 4KW | 0-3000RPM | Ho futhumatsa ka motlakase kapa ka mouoane | -0.09 |

| SME-DE 200L | 200L | 3KW | 0-63RPM | 5.5KW | 0-3000RPM | Ho futhumatsa ka motlakase kapa ka mouoane | -0.09 |

| SME-DE 300L | 300L | 3-5.5KW | 0-63RPM | 11KW | 0-3000RPM | Ho futhumatsa ka motlakase kapa ka mouoane | -0.085 |

| SME-DE 500L | 500L | 4-7.5KW | 0-63RPM | 15KW | 0-3000RPM | Ho futhumatsa ka motlakase kapa ka mouoane | -0.08 |

| SME-DE 1000L | 1000L | 7.5KW | 0-63RPM | 15KW | 0-3000RPM | Ho futhumatsa ka motlakase kapa ka mouoane | -0.08 |

| SME-DE 2000L | 2000L | 11KW | 0-63RPM | 18.5KW | 0-3000RPM | Ho futhumatsa ka motlakase kapa ka mouoane | -0.08 |

| Tlhokomeliso: Haeba data e sa lumellane le ntlafatso ea tekheniki kapa ho fetoloa, ntho ea 'nete e tla tlameha ho etsoa. | |||||||

| Tlhaloso | |

| Mochini oa ho kopanya li-vacuum oa SME-DE o kopanyang homogenizing | |

| Bokgoni | 10-2000L |

| Tšebeliso | Setlolo sa litlolo, peista, setlolo, lotion, gel, conditioner, lebese, sauce |

| Sekhahla se phahameng sa ho kuta | ka tlase ho 2um |

| Karolo ea ho ikopanya | SS316L (lijakete tse tharo. Likarolo tsa thepa ea ho ikopanya lia amoheloaSS316L, Tse ling kaofela ke ss304 |

| Lebelo la homogenizer | 0-3000rpm |

| Lebelo la ho phunya | 0-63rpm |

| Ho futhumatsa | mouoane/motlakase |

| Ho sebetsa | PLC |

| Mofuta | 1. Mofuta oa lift (Sistimi ea ho phahamisa ea Hydraulic) |

| 2. Mofuta o tsitsitseng (sekoahelo ha se khone ho phahamisoa) |

Sehlahisoa se Hlalositsoeng

Tlhahiso ea Morero oa Sesebelisoa sa ho Kopanya le ho Sireletsa sa Vacuum sa SME-DE

Tanka ea Oli

Ho Kopanya ka Tsela e 'Meli le ho Kopanya Ribone ea Helical

Homogenizer e ka Tlase e nang le Potoloho ea Ka Hare

Khabinete ea motlakase ea taolo ea PLC

Sekirini sa Simone se Amanang

Taolo ea ho Laola

Sesebelisoa sa ho fetolela maqhubu a Siemens

Motlakase oa Schneider

simatic s7-200 smart(PLC)

Mechini e Amanang

Ho paka le ho Romela

Boemo ba Khoebo

Ka tšehetso e tiileng ea Profinse ea Jiangsu Gaoyou City Xinlang Light

Fektheri ea Mechini le Lisebelisoa tsa Indasteri, tlas'a tšehetso ea setsi sa meralo sa Jeremane le indasteri ea naha ea leseli le lipatlisiso tsa lik'hemik'hale tsa letsatsi le letsatsi, 'me mabapi le baenjiniere ba baholo le litsebi e le motheo oa theknoloji, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. ke moetsi oa litsebi oa mefuta e fapaneng ea mechini le lisebelisoa tsa litlolo 'me e se e le khoebo ea lets'oao indastering ea mechini ea lik'hemik'hale ea letsatsi le letsatsi. Lihlahisoa tsena li sebelisoa liindastering tse kang: litlolo, meriana, lijo, indasteri ea lik'hemik'hale, lisebelisoa tsa elektroniki, jj., li sebeletsa likhoebo tse ngata tse tummeng naheng ka bophara le machabeng joalo ka Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japane Shiseido, Korea Charmzone, France Shiting, USA JB, jj.

Morero

Bareki ba tšebelisano-'moho

Tšebeletso ea Rōna:

Letsatsi la ho tlisa ke matsatsi a 30 feela

Moralo o ikhethileng ho latela litlhoko

Fektheri ea tlhahlobo ea video ea Upport

Tiisetso ea lisebelisoa bakeng sa lilemo tse peli

Fana ka livideo tsa ts'ebetso ea lisebelisoa

Video ea Upport hlahloba sehlahisoa se felileng

Setifikeiti sa Thepa

Moikarabelli

Mofumahali Jessie Ji

Selefouno/Sesebelisoa sa eng/Wechat:+86 13660738457

Imeile:012@sinaekato.com

Webosaete ea semmuso:https://www.sinaekatogroup.com